ERPNext’s cloud manufacturing ERP.

Reduce errors and increase revenue with a manufacturing ERP with all the features needed for success. Real-time data makes for sound decisions that moves businesses towards profitability.

Reduce errors and increase revenue with a manufacturing ERP with all the features needed for success. Real-time data makes for sound decisions that moves businesses towards profitability.

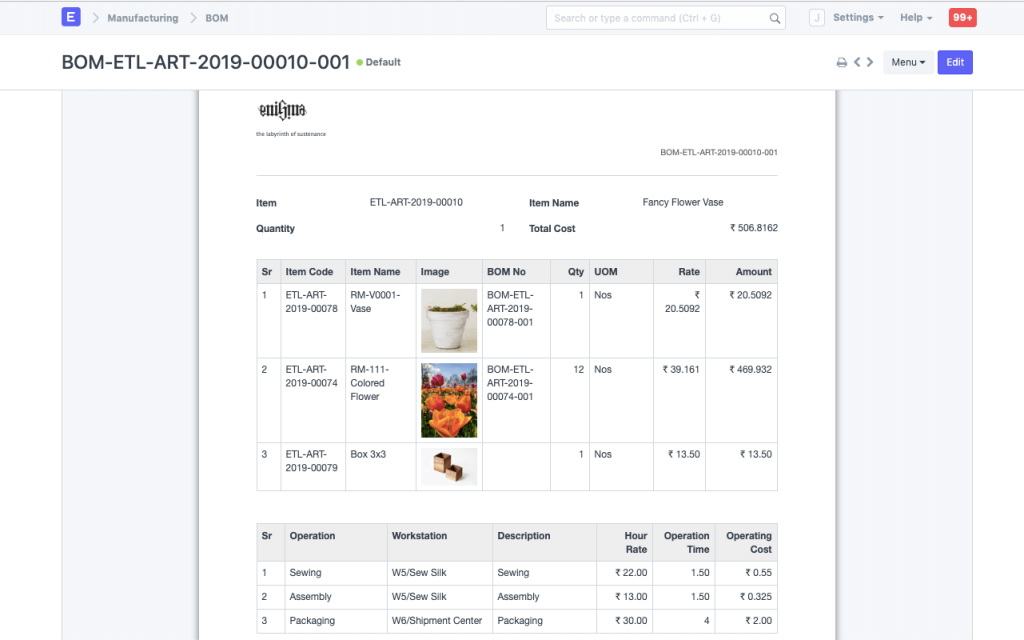

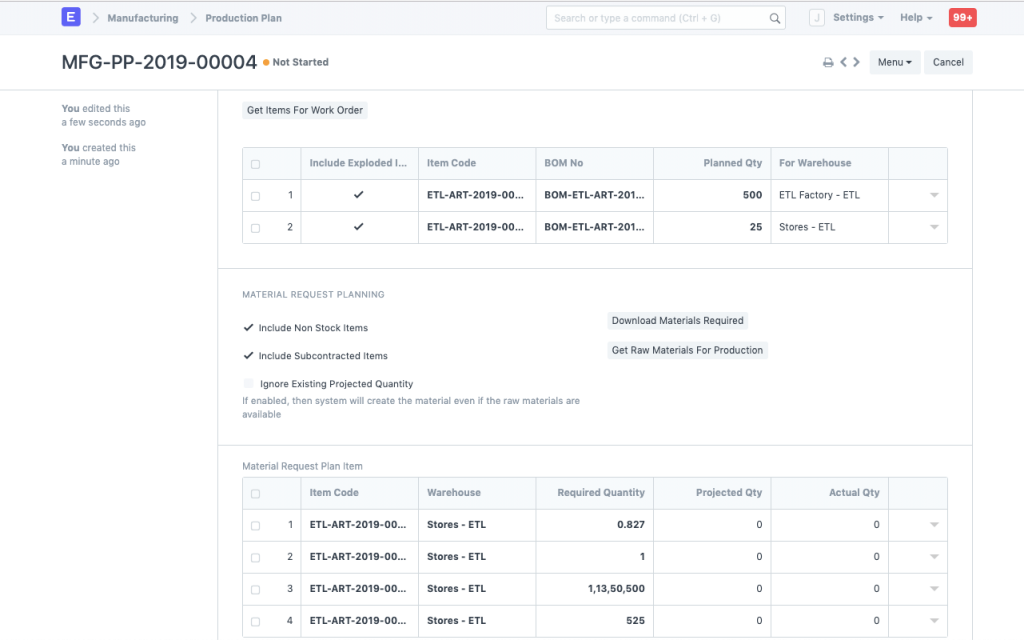

A bill of material is the most critical piece to any manufacturing software, and a well-executed BOM establishes accuracy and provides comprehensive data. ERPNext’s BOM includes product codes, part descriptions, quantities, costs, and additional specifications.

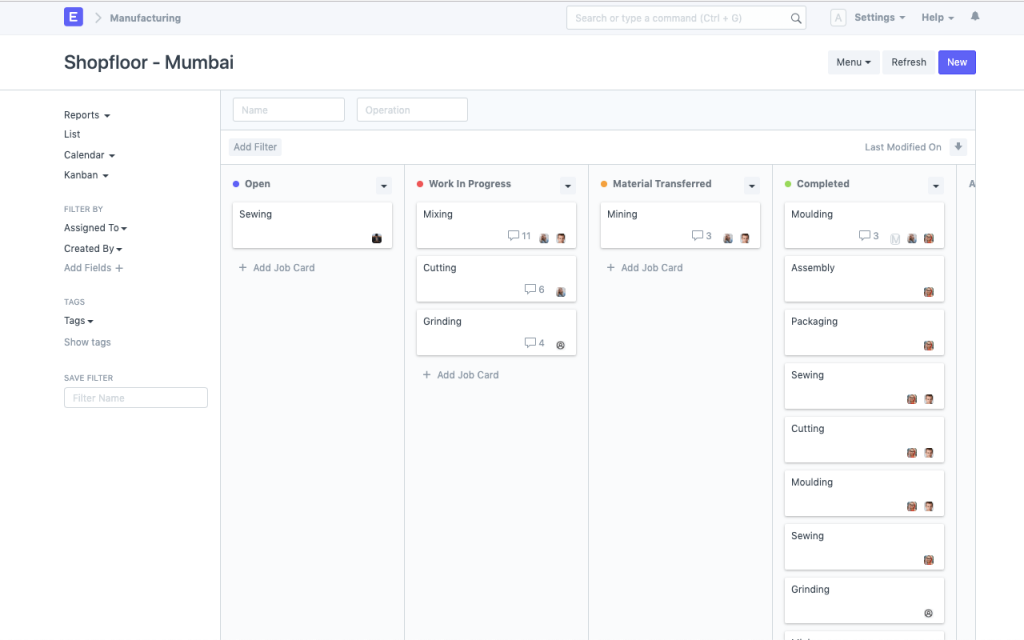

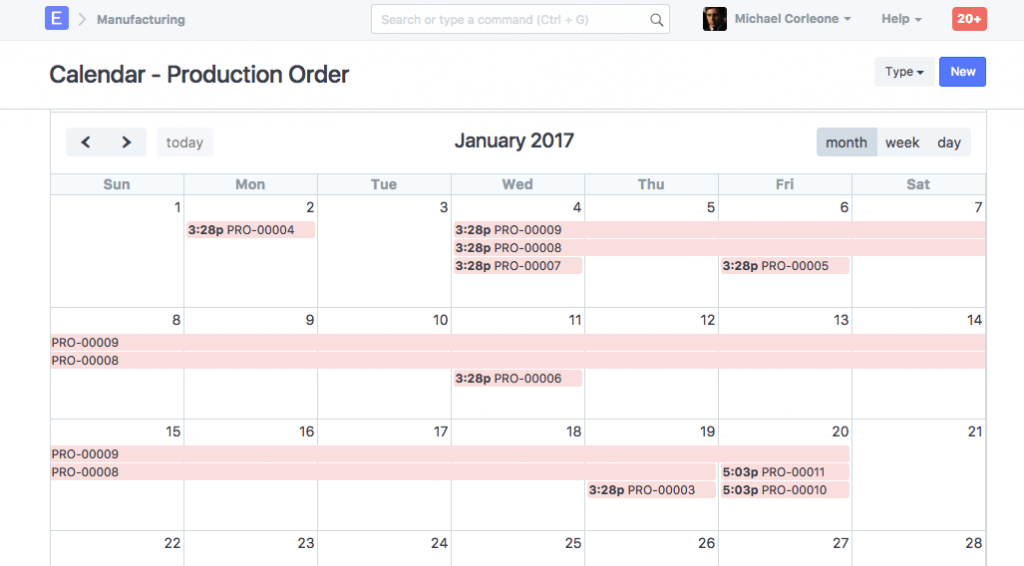

Operations, workstations, and job cards will automatically capture the daily activities of your shop floor in ERPNext. On one screen users can view the real-time status of a job, the workstations, employee assignments, pending steps, and work orders.

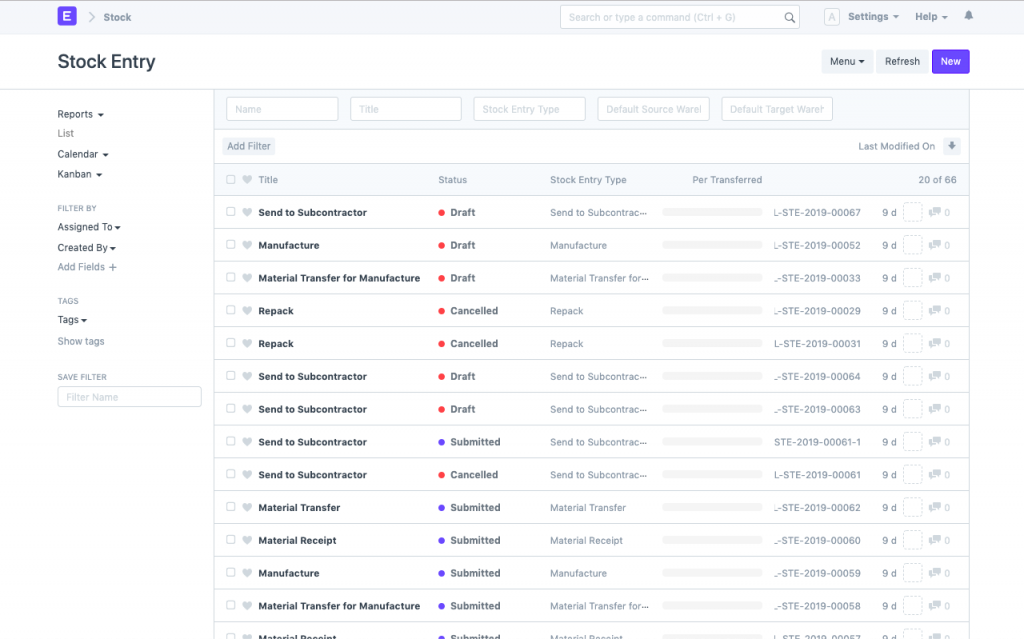

Does your business involve outsourcing processes to a supplier? ERPNext determines the value of sub-contracted goods based on the cost of procured services and raw materials. Easily supply raw materials, track suppliers, and their labor and operations.

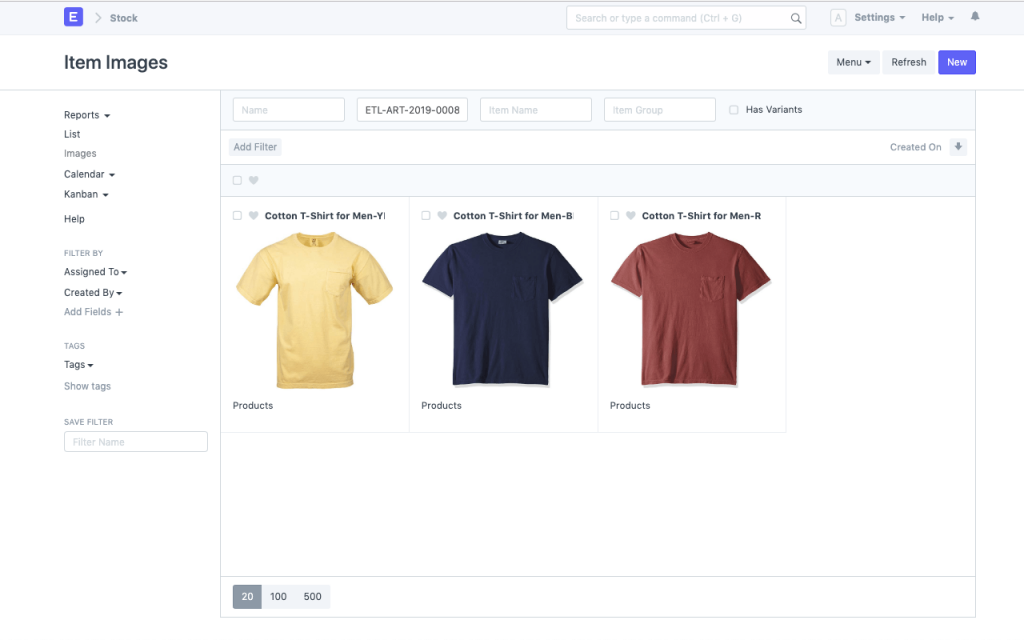

Easily manage products with variants like color, size, or shape. ERPNext allows users to create item templates as the parent item and have multiples SKUs and variations of the parent.

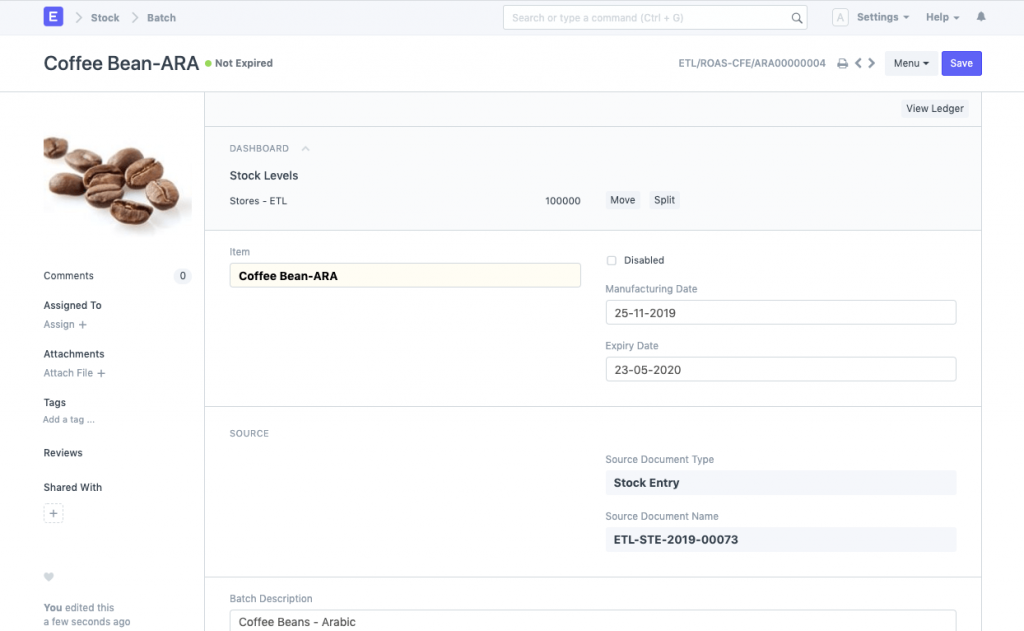

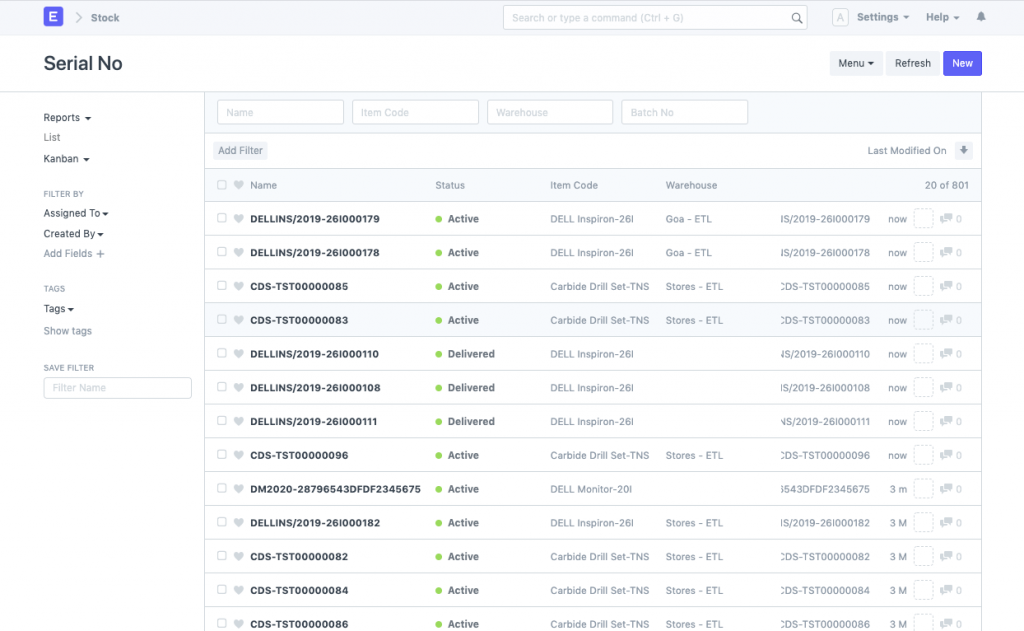

With ERPNext’s integrated inventory, managing batched items is simple. Its real-time view of product availability maintains each batch’s manufacturing dates, expiration dates, and other details. You can even scan item barcodes with your device camera to quickly search through your stock and make data-driven decisions.

Easily manage products with variants like color, size, or shape. ERPNext allows users to create item templates as the parent item and have multiples SKUs and variations of the parent.

With ERPNext’s integrated inventory, managing batched items is simple. Its real-time view of product availability maintains each batch’s manufacturing dates, expiration dates, and other details. You can even scan item barcodes with your device camera to quickly search through your stock and make data-driven decisions.

Easily manage products with variants like color, size, or shape. ERPNext allows users to create item templates as the parent item and have multiples SKUs and variations of the parent.

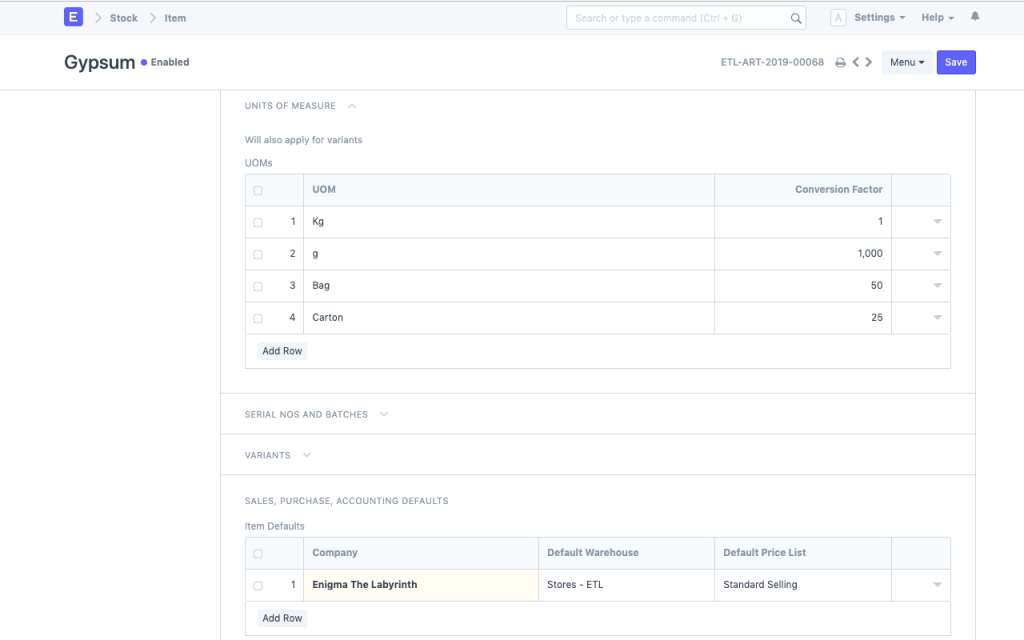

ERPNext supports hundreds of different units of measure right off the shelf. Each item can have its own conversion factors as well as different units of measure for buying and selling. Conversions are automatically handled by the system.

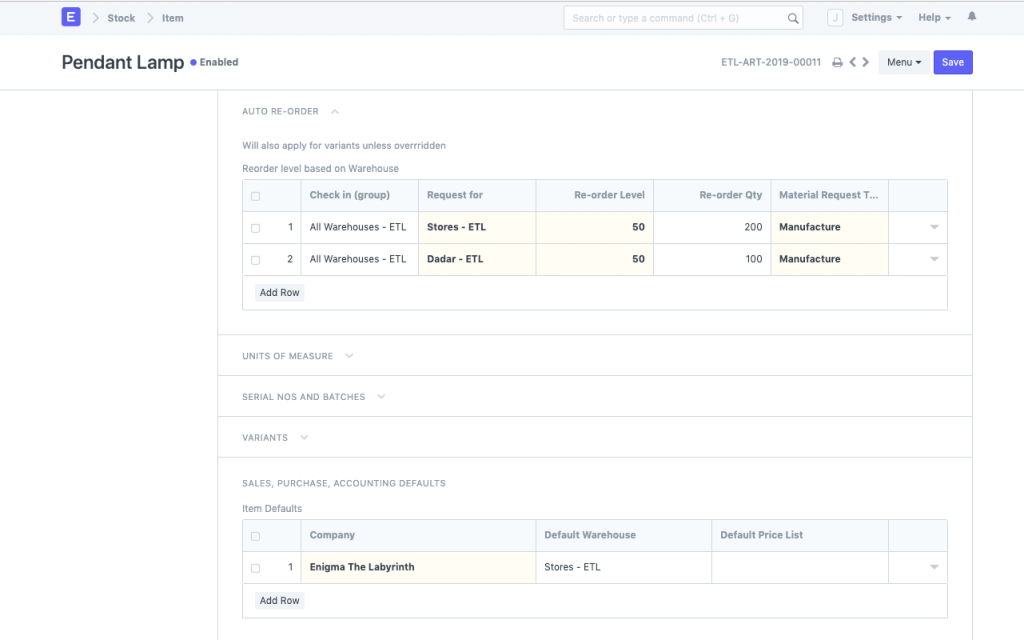

Custom settings for re-stocking. When the stock level goes below your reorder level, ERPNext can automatically create a material request. This helps you replenish inventory at exactly the right time and reduce the chances of going out-of-stock.

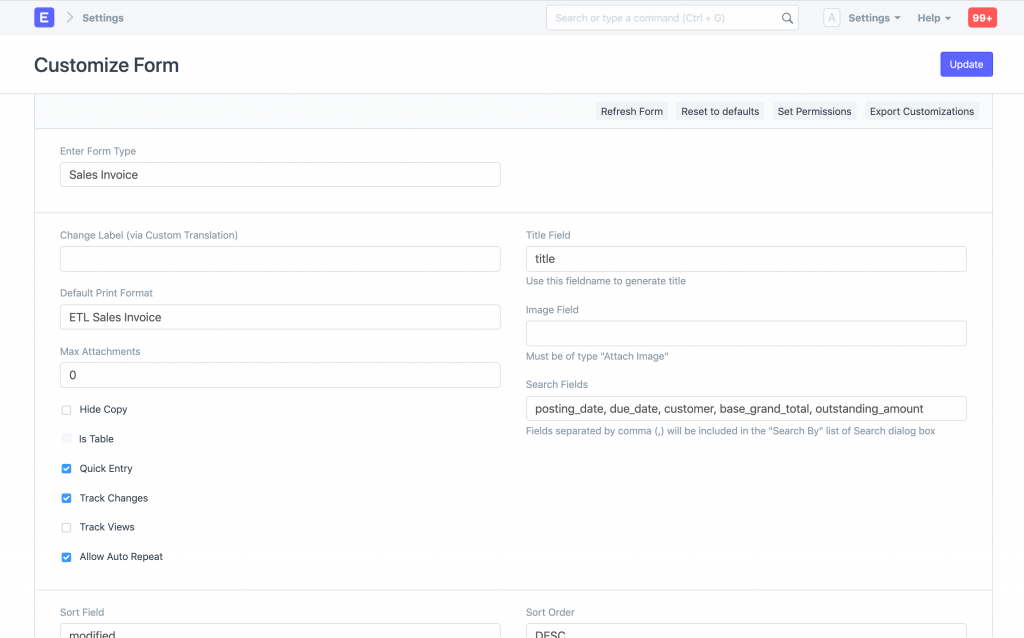

Create your own custom cloud manufacturing ERP software. Map your most important data by adding custom fields in your forms. Customize form behavior by auto-fetching values, hide fields based on user roles, and create custom print formats — all without a single line of code.